Hydraulic Shock Absorber max impact 252 mm - Designed for Sliding Fire Doors - 65000SV Opera

Use of Hydraulic Shock Absorber for Closing Safety Doors

Hydraulic shock absorbers are used as a limit switch to slow down the impact and therefore facilitate the closing of a sliding door thanks to the braking effect deriving from the passage of oil through holes and slots made in the cylindrical body.

By means of a

regulation system, the degree of braking can be increased or decreased by opening or closing the oil passages through the piston.

The damper stem, once compressed, rearms automatically when the door is reopened by means of a special magnet, preparing itself for a new cycle.

Version - Opera 65000SV Hydraulic Shock Absorber

Short hydraulic shock absorber max 252 mm.

Choice of safety valve

- With safety valve

- Without safety valve

- (The safety valve is used to let the brake fluid out in case of fire and to avoid the spontaneous rearming of the piston rod due to the thermal expansion of the liquid)

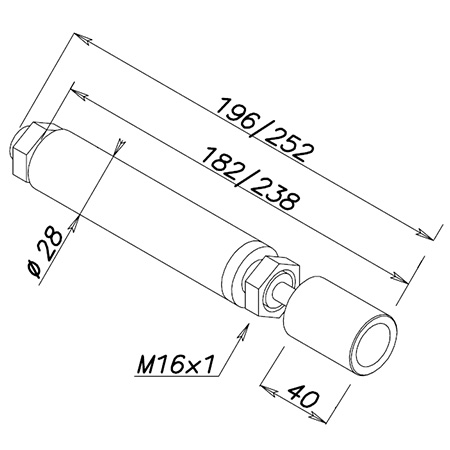

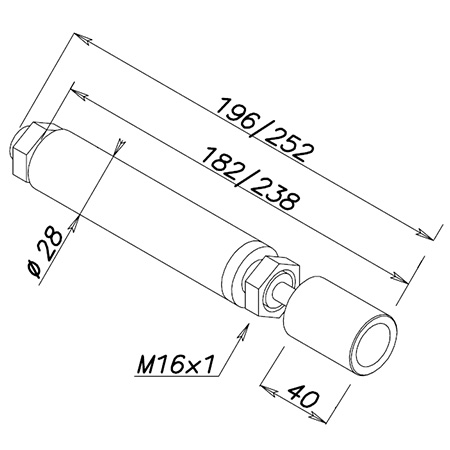

Technical features - Opera 65000SV hydraulic shock absorber

- Cylindrical body in galvanized steel

- Diameter of body and magnet: mm. 28

- Minimum total length including magnet: mm. 196

- Total length in maximum extension: mm. 252

- Stroke: mm. 56

- Hydraulic cushioning system

- Shock absorber hardness adjustment

- Fixing with threaded terminals M 16 x 1

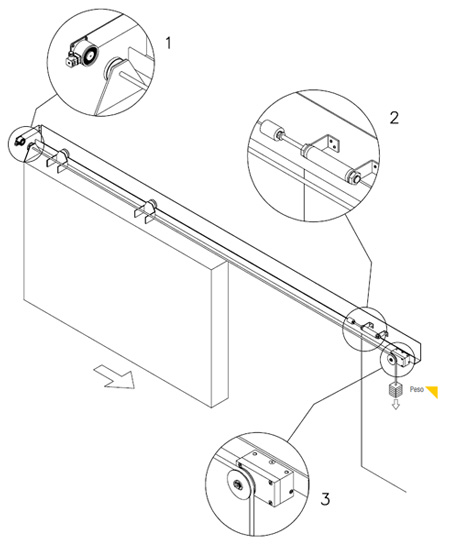

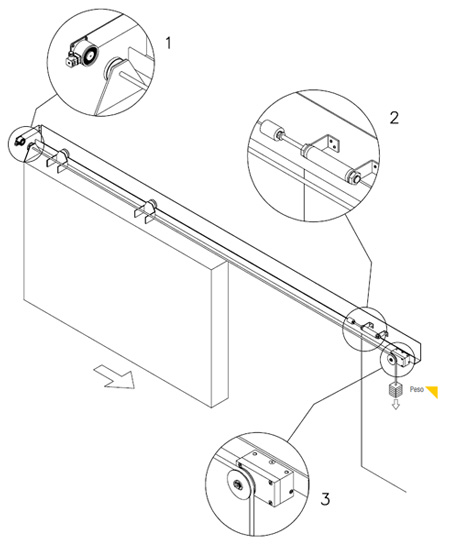

Example of use of the damper on a sliding door

1 Electromagnet

2 shock absorber

3 Closing regulator

Opera operating access

Opera srl, specialized in the design and production of electric handles, was created in 1997 in Modena, in Emilia Romagna, land of food and engines. All the management of the company comes from the experience of Corni locks which has been present in the city of Modena for over a century.

The company is characterized by continuous expansion in world markets but with strong roots in Italy.

Opera Made in Italy production

Over 40% of our turnover is made abroad, but 90% of our suppliers are local. Almost all of the products are manufactured in our modern industrial plant, with technologies that respect the environment and work quality. We are proud to produce and live in Modena, a town in northern Italy which has been a UNESCO World Heritage Site since 1997.